Sorry, this entry is only available in Russian.

Month: September 2020

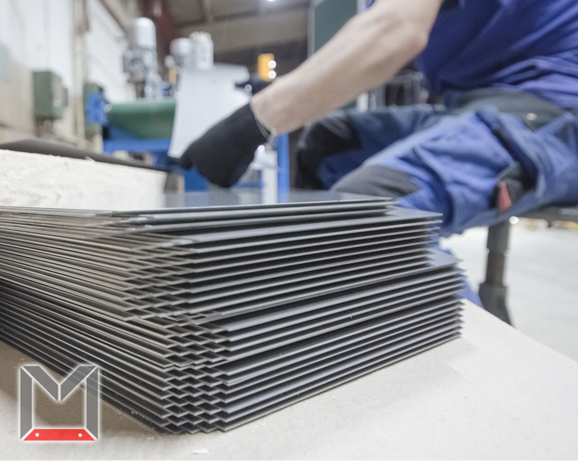

Sharpening of dies and punches

The tool section of our company offers services for sharpening the following tools on surface grinding machines:

- matrices

- punches

- stamps

- guillotine knives

- etc.

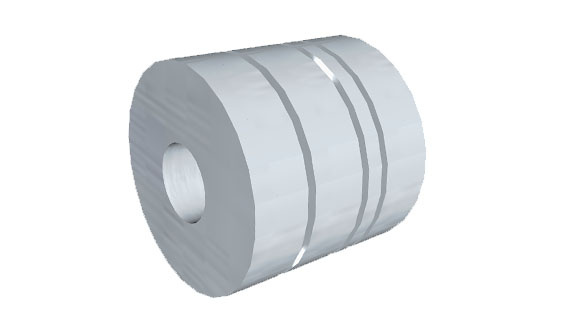

Longitudinal cutting

Our company is ready to make longitudinal cutting of coiled electrical steel into strips (subcoils) from the customer’s material.

The line, put into operation in May 2020, allows obtaining a consistently high quality and significantly reducing the period for cutting strips for further processing.

Equipment capabilities:

- Cutting electrical steel up to 0.5 mm thick (including grades NV30S-120, NV30S-130, T111-30s, T130-30S, M400, etc.)

- Mother coil width up to 1250 mm

- Mother coil weight up to 5 tons

- burr on the edge, no more than 20 microns

- deviation in roll width no more than 0.1 mm

We will be happy to provide our partners not only with services for the manufacture of assembled magnetic cores, but also separate longitudinal cutting of electrical anisotropic and isotropic steel into strips.

New equipment: Slitting line

Continuous improvement is one of the main goals of the company “Magnitola”. That is why we strive to expand the machine park, as well as upgrade existing equipment. We present a new slitting line for electrical steel (both transformer and dynamic). Launched in may 2020, the line allows us to get consistently high quality and significantly reduce the time of cutting strips for further processing.

Hardware features:

- Cutting of electrical steel up to 0.5 mm thick (including NV30-120, NV30-130, T 111-30s, T 130-30S, M400, etc.)

- Initial roll width up to 1250 mm

- Weight of the initial roll up to 5 tons

- edge Burr, no more than 20 microns

- roll width deviation no more than 0.1 mm

We are glad to provide to our partners not only services for the manufacture of magnetic cores, but also with a separate longitudinal cutting of electrical anisotropic and isotropic steel into strips.

info@step-lap.com

info@step-lap.com +7 495 740-61-78

+7 495 740-61-78