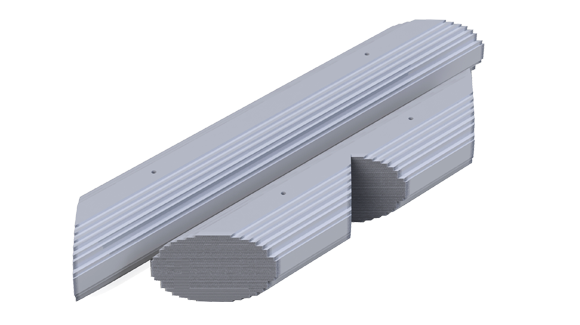

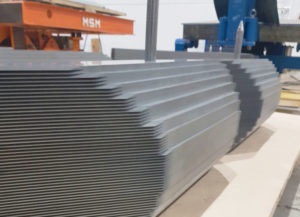

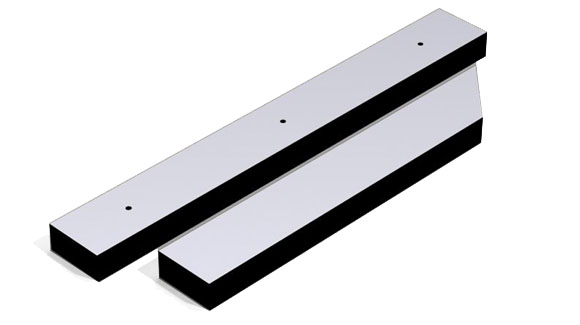

Magnitosila specializes in the production of magnetic cores not only of standard configurations for power three-phase transformers. The scope of our capabilities includes the manufacture of almost any charge specialized magnetic cores.

Our reference list includes:

- single-phase and three-phase magnetic cores for induction furnaces;

- magnetic cores for arcing reactors;

- magnetic cores for regulatory systems;

- magnetic cores of quenching plants;

- magnetic circuits for water-cooled inductors

- and many others.

Experienced designers and engineers of our plant are ready to adapt the customer’s documentation to modern materials and technologies, as well as to develop a magnetic circuit design in the complete absence of design data (from a living sample or according to the technical task).

info@step-lap.com

info@step-lap.com +7 495 740-61-78

+7 495 740-61-78