Technical information

Types and design features of manufactured magnetic cores

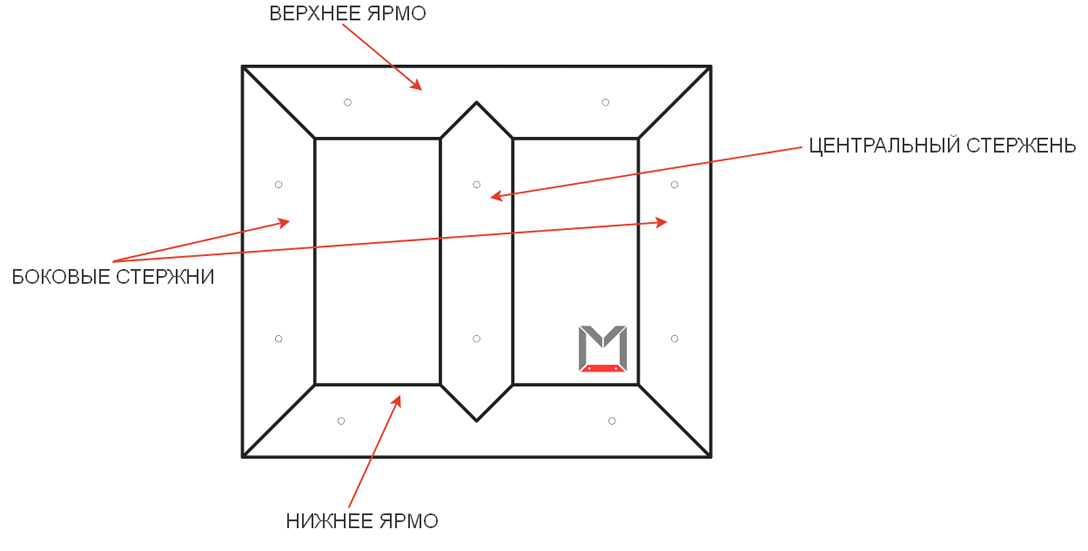

Transformer and reactor core is a closed (usualy for transformers) or open (applied in various reactor types) magnetic circuit, used to guide magnetic flux. Mostly core has two, three or five limbs with lower, upper and intermediate yokes. .

THREE-PHASE TRANSFORMER CORE

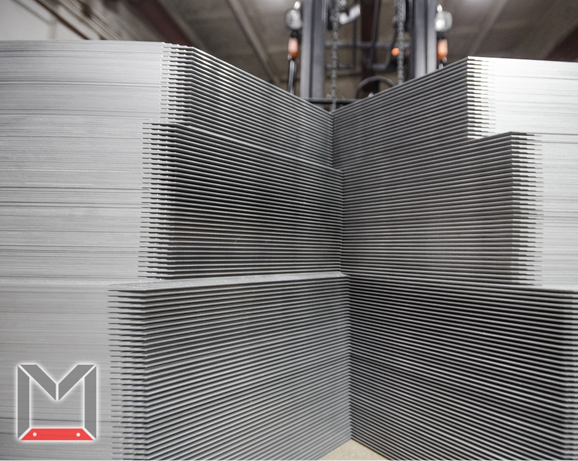

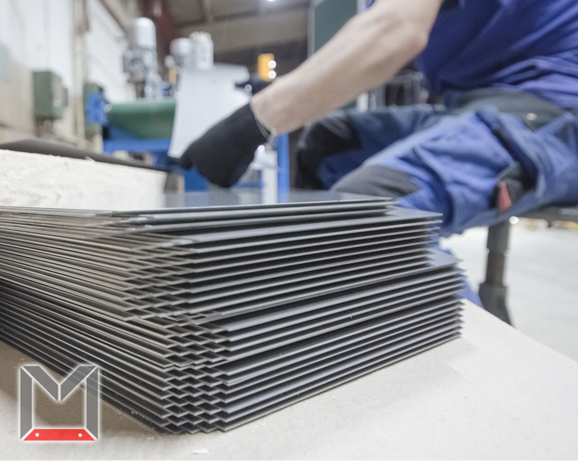

No load losses can be reduced by making core by thin sheets electrotechnical steel which are insulated to each other. Less thikness and high steel quality minimize iron lossses. Other factors also can have significant impact on losses of assembled core – sheets cutting quality, stacking type, holes dimensions and quantity etc. Most common electrotechnical steel in Russia – NV30S-120 (steel thikness 0.3 mm), NV27S-120 (steel thikness 0.27 mm) manufactured by NLMK (Lipetsk), VIZ-Steel (Ekaterinburg).

Core design and stacking type effect on core characteristics. Most common core design is step-lap.

Фото 2 Middle cut in sheets of yoke for central limb.

Фото 3 Central limb of step-lap core

In this type of core design all joints has 45 degrees. There are also wind cores, 90 degrees joint cores – more cheaper in manufacturing but suffer from some drawbacks compared to step-lap core (noise level, mechanical strength, maximal induction, losses in core joints)

ТЕХНИЧЕСКИЕ ВОЗМОЖНОСТИ НАШЕГО ОБОРУДОВАНИЯ:

- sheets width from 50 up to 490 mm

- standard steel is NV30S-120

- hole diameters 11, 17, 22, 26, 30, 32 mm