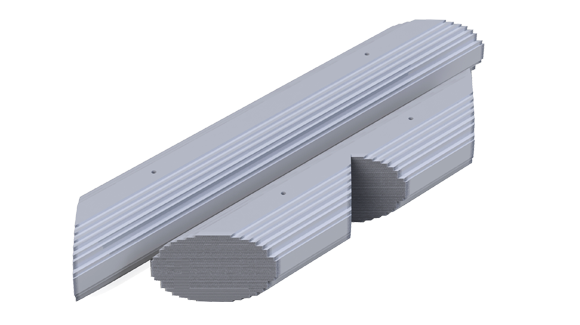

STEP-LAP technology in the manufacture of magnetic cores can significantly reduce no load losses in the finished product (compared to a combined joint). This is especially true in the production of power and distribution transformers with capacities above 160 kVA.

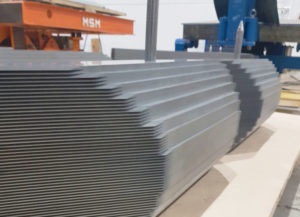

The capabilities of our production allow us to produce and ship individual sheets of magnetic cores to the customer. The need for separate sheets is relevant if the customer has his own section for assembling magnetic cores. At the same time, the site must have specialized equipment, equipment and qualified personnel

The transverse cutting of electrical steel for magnetic cores according to the “step-lap” technology is a set of magnetic circuit plates laid in bags on pallets. Steel grade, plate geometry (see the section on technical production capabilities), step-lap parameters, requirements for stacking packages and fixing plates on pallets can be made in accordance with customer requirements.